Trenchless Sewer Pipe Replacement

|

"Trenchless" replacement or "pipe bursting", HDPE Slip and "tight" Lining ,CIP re-lining and GROUT repair.

How Does it work? We use 4 basic methods to replace/repair fibre/pitch and other earthenware and plastic pipes. Have a look at our RECENT PROJECTS. 1. The first is "pipe bursting". This is a particularly effective and preferred method of replacing 110mm sewerage pipe without having to dig trenches! A cable is pulled through the old broken pipe. When this is done a "pig" or "bullet" is attached to the cable. The back of the pig is attached to a roll of new HDPE pipe. A specialised hydraulic winch is used to draw the plug through the old sewerage pipe, bursting it open and drawing the new pipe in behind it. This method has a number of obvious advantages. You don't mess up the paving, driveways, gardens, walls etc. We are able to draw the pipe under buildings and walls! In some cases there is in fact no other way to replace the pipe - particularly when you have to go underneath a building. The new pipe is the same bore size as the old! You cannot burst through bends however. We have developed a special "small footprint" , mini machine that only need a hole of 1m x 1m. This causes a minimum of disruption and the machine is very easy to set up in a confined space. We are as far as we know the only company in SA that is able to scale pipe bursting to this small footprint.

Hydraulic winch used to pull new pipe through the old. 2. HDPE Slip (tight) re-lining - We also use a slightly smaller bore (100mm) pipe to replace the 110mm. Domestic sewerage pipes seldom run "full bore". The slight reduction of bore causes the water to run slightly faster, reducing any tendency to block. It wont block anyway, because the pipe is smooth inside - no joins or obstructions. This is a particularly cost effective solution to replacing "black" fibre/pitch pipe. It can be done quickly with minimal resistance in the hole (no "bursting") and is often cheaper than digging the pipe up! This method has all the advantages of pipe bursting (above) but is easier and quicker to do. There is a slight complication at the join at the upstream end - but we have never found this to be a major issue. For some good reference material on slip lining and bursting, have a look at http://www.hammerheadmole.com For more info on pipe materials and sizing look at sizing.

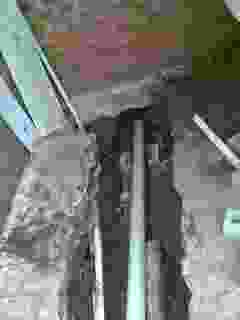

Right under the front door!

HDPE lining is a clear winner in many ways - 1. Its fast - although it does take a bit of time to dig the pits, the actual pipe replacement can be done in under 2 hours (30m). This means that the disruption to the sewerage system is minimal. 2. Very little mess and minimal destruction - you don't end up with a massive ditch across your garden and through your driveway and paving. Digging is restricted to a small pit every 25m. 3. You don't have to pay extra to re-route your pipes around buildings and walls - we use the same pipe layout as before. 4. Your sewer line retains its fall. When you reroute you often find that the rerouted section ends up with NO fall and never works properly! 5 The pipe that we use (Class 6+ HDPE) is twice as strong as modern 110mm PVC sewer pipe. See HDPE 6. There are no joins to tempt tree roots - we use a continuous pipe between pits. And the pipe is smooth inside - flow is improved. 7. The round pipe profile is restored. The bursting pig reforms the hole and makes a flat pipe round again. It also cuts through obstructions allowing the new HDPE pipe to be pulled in behind it. 8. Accumulated waste matter and contaminated soil stay in the ground - we pull the new pipe through it. 9. Unusually deep systems do not cause dramatic cost escalations - it's only the pits that need to be deeper - not an entire ditch. 10. Cleanup and rehabilitation after the job is done takes minutes rather than days.

Pig breaking through at the end of a 110mm pipe burst. So if its so great then why doesn't everyone do it? A good question that is fairly easy to answer. There are a number of companies in South Africa that are doing heavy pipe bursting/cracking/jacking on an industrial scale. The equipment that they use is big, incredibly expensive to buy and all imported from the USA, Germany and other countries. They do sometimes do small (down to 110mm) lines in desperate circumstances - like under a building - but their systems do not really scale down very well - they use the industrial grade machines to pull the tiny (in comparison to what they can pull) 110mm pipes. They need pits of up to 4m long and often need a crane to lower the equipment into place. Costs can run up to R10k/m. We have developed our own equipment over the last 7 years and it is made locally for our specific requirements. We have focused specifically on the replacement of 110mm fibre/pitch pipe (although we can do other materials up to 160mm) and we have scaled all our equipment so that it can easily be wheeled into your back garden and set up in minutes. We can in fact take our equipment through your house if we really needed to! We don't know of anyone else in SA who has scaled it down as far as we have. We have costed our service to compare favorably with the traditional means of digging up and replacing the line - and in many areas we are in fact cheaper. We are always cheaper when it comes to very deep systems and when it comes to not causing damage to roads, driveways, buildings, walls and paving. Are there any limitations to this method? Yes - there are a few, but they make little difference to the success of most projects. 1. We only pull in straight lines - we don't go around corners. A change of direction dictates an additional pit. 2. Junctions have to be done manually. 3. We occasionally get stuck - either because of rock, or more commonly because someone has poured concrete over the pipe. In this case we dig up a small section to get to the concrete and break it up.

New run of 110mm HDPE joined to the old system.

3. Cured in Place fibre lining. In many cases, where the pipe is still intact it may be more appropriate to re-line the inside of the pipe with fibre/resin. We employ a similar process but we don't "burst" the pipe - we reform it, clean and dry it. We then insert a lining material to seal it.The resin based lining is "cured in place" (cip). We are the South African Agent for a specialist company in the UK Renoline, Who make high quality re-lining systems. Fibre/pitch (black) pipes should generally not be relined in this manner.

The customer will benefit from the Renoline repair process in many ways.

Chemical Grout Injection. This is a very cost effective method of repairing earthenware (clay pipes) pipes - see Grout Injection Method. We use trenchless methods to replace or repair "fibre pitch" pipe wherever possible. The cost of these methods compare favorably with traditional methods and it is faster and cleaner. The speed of pipe replacement/repair is a major factor when working in townhouse complexes that cannot be without sewerage facilities for a week while the pipe is being dug up! The cost/meter is comparable with traditional digging and in fact cheaper in many applications, if you elect to use 100mm slip lining. Have a look at our RECENT PROJECTS or call Lee on 083 458 4836 for more information. info@blockbusterdrain.co.za

110mm HDPE being drawn through the old fibre/pitch pipe. Our machine is very compact and can be used in confined spaces. It can be carried by hand and needs a 1x1m pit at the "destination" end. The "source" pit needs to be about 2x 0.5m to accommodate the new pipe being fed in. In the case of a CIP liner you may not need to dig at all. The liner can be inserted from the manhole end.

|